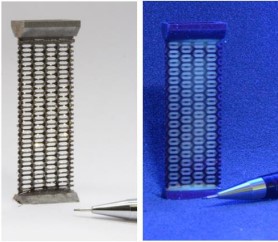

Flexure-based mechanisms have become state-of-the-art solutions for the design of high-precision mechanisms, free from friction wear, backlash, and lubrication. These properties which are necessary for applications in ultraclean or harsh environments, nevertheless usually come with the drawback of very high quality factors. High quality factors can lead to adverse vibrations in the case of highly dynamic motions, or even fractures in the case of mechanical resonances. In space applications for instance, the mechanisms experience shocks and vibrations resulting from the rocket launch and from the other subsystems during operation. To tackle this challenge, CSEM developed and validated a concept of damped flexure blades based on bi-material additive manufacturing. The blades consist of a sandwich of two planar parallel metallic lattice patterns with an elastomer impregnated in-between (125 μm gap). The blades are made of 17-4PH stainless steel manufactured by Laser Powder Bed Fusion. The damping effect results from the energy dissipation occurring in the viscoelastic material as the blades and the elastomer deform. These blades were assembled in a simple parallel-spring-stage configuration and characterized under free and forced sinusoidal oscillations. Compared with reference mono-material “undamped” flexures, the damped flexures show quality factors Q reduced by a factor of 64. This reduction implies an improved damping action with a calculated viscous damping coefficient increased by a factor of 97. These first experimental results open promising perspectives for compliant mechanisms operating under vibrations and shocks. Moreover, new types of dampers could be developed based on the presented designs.

Source: Proceedings of the 23rd International Conference of the European Society for Precision Engineering and Nanotechnology